In any modern workshop or production facility, especially in woodworking, dust is more than just a byproduct — it’s a challenge. Left unchecked, it can compromise air quality, reduce the lifespan of machinery, and increase energy costs. This is why an efficient dust extraction system is not just a convenience; it’s essential. But while we often focus on large filters, powerful fans, and central control units, it’s easy to overlook the smaller components — the ones that quietly ensure the entire system runs smoothly.

At JKF, we believe that a small part can make a big difference. Our Pneumatic Sliding Damper is one such component: compact, practical, and smart — yet central to maintaining a reliable and energy-conscious dust extraction setup.

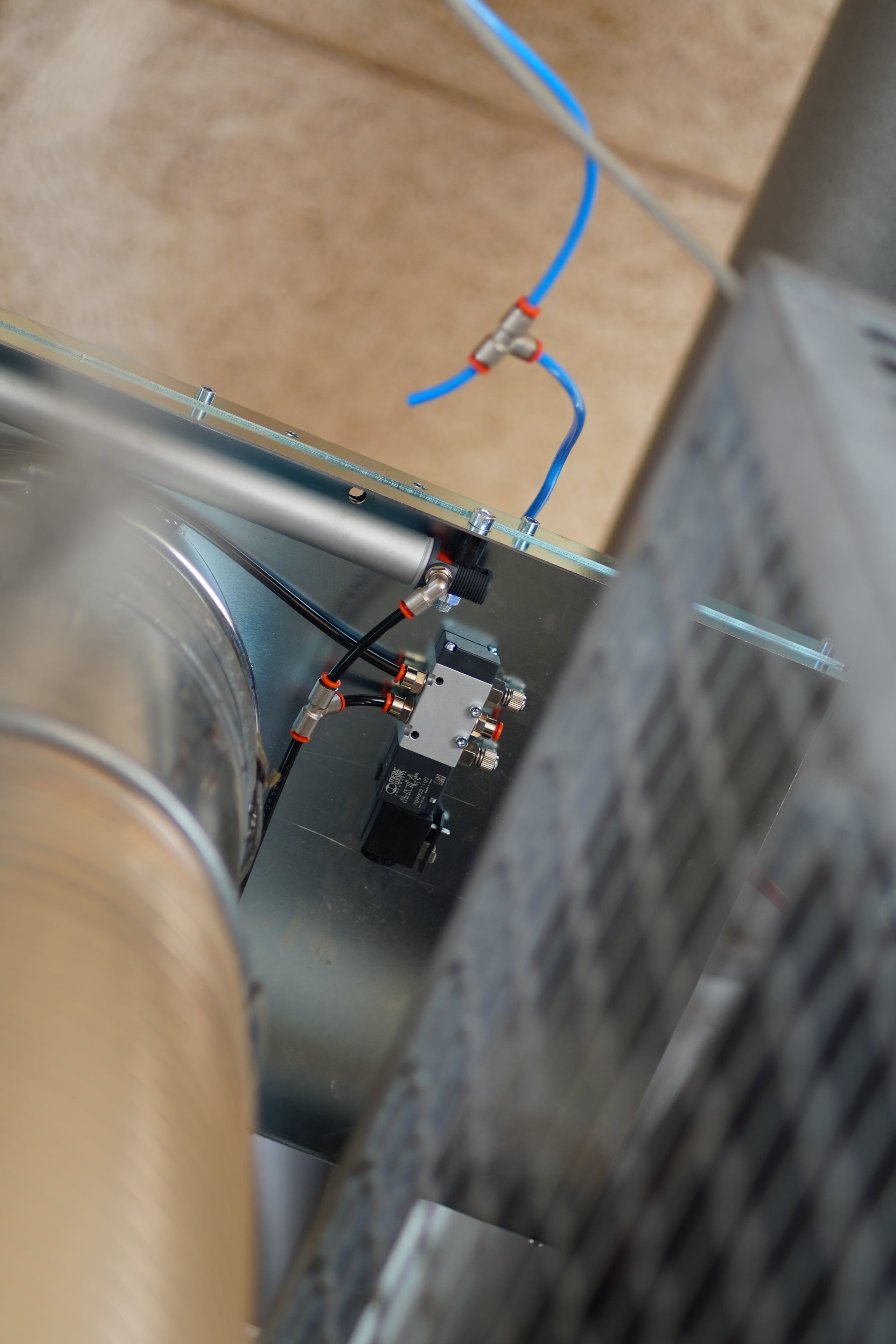

The JKF Pneumatic Sliding Damper may appear simple at first glance, but it's been carefully engineered with functionality and long-term performance in mind. At its core is high-quality control, powered by trusted components from Metalwork Pneumatic, known for their reliability and durability across industrial applications.

For sizes ø80 to ø200, the damper features an integrated guide rail. This ensures a straight, low-friction slide and prevents tilting — reducing wear and helping to maintain consistent airflow throughout the system.

One of the most appreciated upgrades is the built-in LED indicator. With just a glance, operators can confirm whether a damper is open or closed — eliminating the need for manual inspection and reducing the chance of human error. In busy workshops, this simple feature saves time, streamlines workflow, and improves overall system oversight.

And when the demand increases, the design holds strong. For sizes ø180 and above, the damper comes with two pneumatic cylinders for added stability and smoother operation — especially valuable in larger, high-capacity installations.

Manual dampers are often forgotten — left open even when machines are idle. This leads to unnecessary air extraction, higher energy consumption, and premature wear on the entire system. By integrating the Pneumatic Sliding Damper with a solenoid valve, JKF offers a way to automate airflow management: extraction only happens when needed.

This small adjustment in how a damper operates can significantly reduce energy use and contribute to a longer system lifespan. When every component does its job well, the entire dust extraction system becomes more than the sum of its parts — it becomes a coordinated, efficient, and sustainable solution.

A woodworking customer recently upgraded to the JKF Pneumatic Sliding Damper, even though they had previously used automatic dampers. Their feedback speaks volumes:

"We'd been using automatic dampers before, but JKF's new version is clearly a step forward. The LED indicator alone has saved us time — and the smoother operation makes a big difference. It's one of those upgrades you notice right away."

It's not about reinventing the wheel. It's about making the wheel smarter, smoother, and better integrated into the system.

From new installations to retrofits, the JKF Pneumatic Sliding Damper is designed to fit right in. It's available in sizes ø80 to ø500, with the most common variants in stock and ready to ship. That means less waiting, quicker upgrades, and faster results for customers who need their systems to perform without interruption.

It's an affordable upgrade — especially when considering the energy savings and reduced maintenance it enables over time. And with JKF's dedication to long-term product support, customers know they're getting a solution they can rely on.

At JKF, we understand that dust extraction is about more than just moving air. It's about creating cleaner, safer, and more efficient environments — whether it's in a woodworking shop, a production hall, or an industrial plant. That's why every component we offer is built with a clear purpose and a focus on quality.

The Pneumatic Sliding Damper may be just one part of a larger system, but it's a perfect example of how the right details make all the difference. It helps conserve energy, extends the life of equipment, improves everyday operation, and supports cleaner air — all with minimal fuss and maximum reliability.

JKF – Dedicated to clean air.

Looking for more insights and information on the JKF Universe? Check out our related content.

JKF Ecademy's FAQ section is a helpful resource that offers answers to commonly asked questions about process ventilation. With a wide range of topics, such as system design, installation, maintenance, and troubleshooting, users can easily find the information they need. The section is designed to provide a hassle-free experience, with the option to browse categories or use the search function to quickly locate specific topics or questions.

JKF's dust extraction solutions can support your business in various industries. From the woodworking industry to the agro-milling industry, our team of experts has extensive experience in providing efficient and customized dust extraction solutions that meet the specific needs and requirements of each industry.

Here, you can read informative articles about the various industries, and discover how our products can help you optimize performance, reduce costs, and enhance safety and environmental standards.